Porsche said:

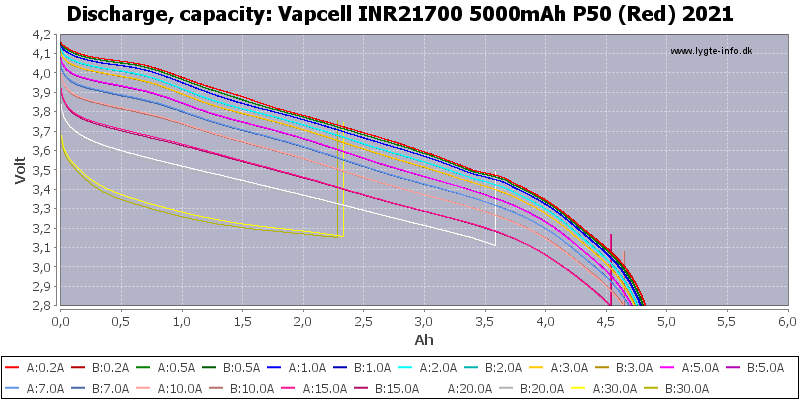

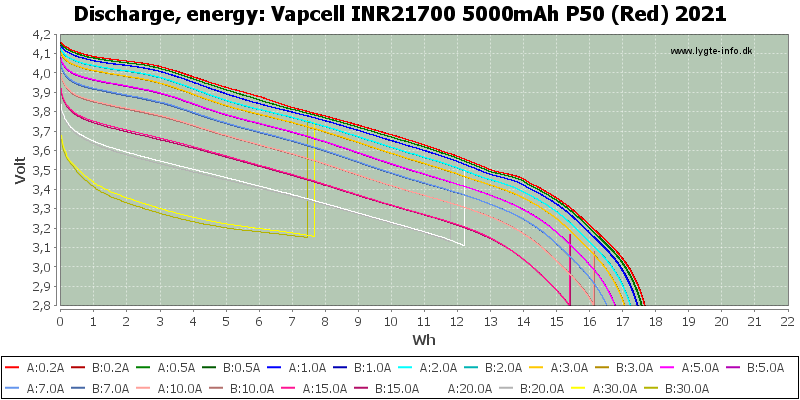

at least to a first order approximation, Li-ion batteries put out pretty close to constant voltage over most of their charge range. All of your graphs pretty much demonstrate this (albeit these are for flashlight/camera batteries, not for cars, but the basic chemistry is the same).

It's actually quite the contrary. The graphs demonstrate a fully charged battery at 4.2 V and fully discharged at a safe 2.8V. With a 1st order approximation, you'd say the voltage varied by 1.4V using only 1 sig fig. 0th order approximation would be 1V, so based on this data, we can't consider the voltage to be constant. Multiply that difference 96 times and we have to work with a voltage range of 268.8V to 403.2V to a 1st order approximation, a difference of 134.4V between fully charged and fully discharged cells. Also keep in mind that EV's of the likes of Tesla that don't use pouch cells will use cells of this construction, so the chemistry and form factor should be a fairly representative comparison for EVs.

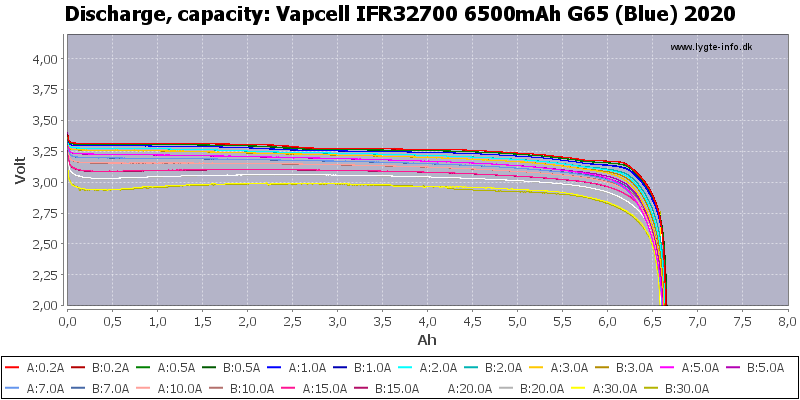

That being said, LIFEPO4 (LFP lithium-ion) has a much more constant voltage range:

https://lygte-info.dk/review/batteries2012/Vapcell IFR32700 6500mAh G65 (Blue) 2020 UK.html

This would be true of the 2014 Spark EV with the A123 LFP cells, so you could argue that, to a 1st order approximation and over roughly 80% of the discharge curve, the voltage remains constant. The low SoC performance should be quite good for the 2014 Spark EV, as well as not suffering as much voltage sag at high C discharges compared to NMC.

the physical limit for discharge for an EV battery is nowhere near 120kW. It's more like a megawatt or more.

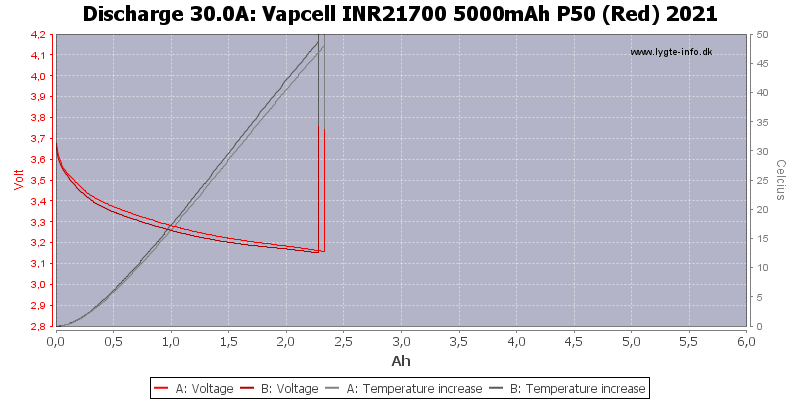

There's a big difference between physical limit and safe physical limit. No EV discharges beyond a C rating specified by the cell manufacturer because going beyond that point irreversibly damages it (plating, destroyed graphite structure for ion intercalation, heat/boiling/vaporizing of electrolyte and pressure causing deformation or budging, ultimate loss of capacity and current capability) as you yourself alluded.

If you want repeatable results as is expected of a car, it must be designed within those safe limits. If you want to design a vehicle with the sole purpose of breaking a land speed record at peak power, you probably don't care for pack longevity.

It really depends on which EV we're talking about, too. Not all EV batteries or their packs are made the same, or with the same capacity and configuration. Max discharge power has a proportionality with capacity, among other limitations. I'd say the Spark's batteries would be hard pressed to release 0.5 Megawatts of stored electrical power safely, even though the batteries used are hybrid batteries which tend to support higher C ratings at low pack kWh sizes compared to higher capacity packs in BEV's.

If this weren't true, not only would the car's efficiency be significantly worse than an ICE car, but would catch fire in minutes, or at least melt (literally, not virtually).

That's a bit of a non sequitur. Take the 2019-2021 Tesla Model 3's as tested and logged on Bjorn Nyland's youtube channel and google drive spreadsheets.

https://docs.google.com/spreadsheets/d/16mGOOveEcxO85bVkp51YG7-DGWijpI7zY8yh6p7VnEw/edit?usp=sharing

https://youtu.be/QGjwEAWTcrw?t=171

A model 3 performance with a hot battery (peak performance ready) has <400kW discharge power and it is easily several times more efficient than an ICE car. SR+ is even less at >240kW. Why would discharge power have to be >500kW for the Spark EV's pack to be more efficient than an ICE either?

Anyways, I'm interested in this peak power claim. My position is that power is going to plateau as the voltage sags to nothing.

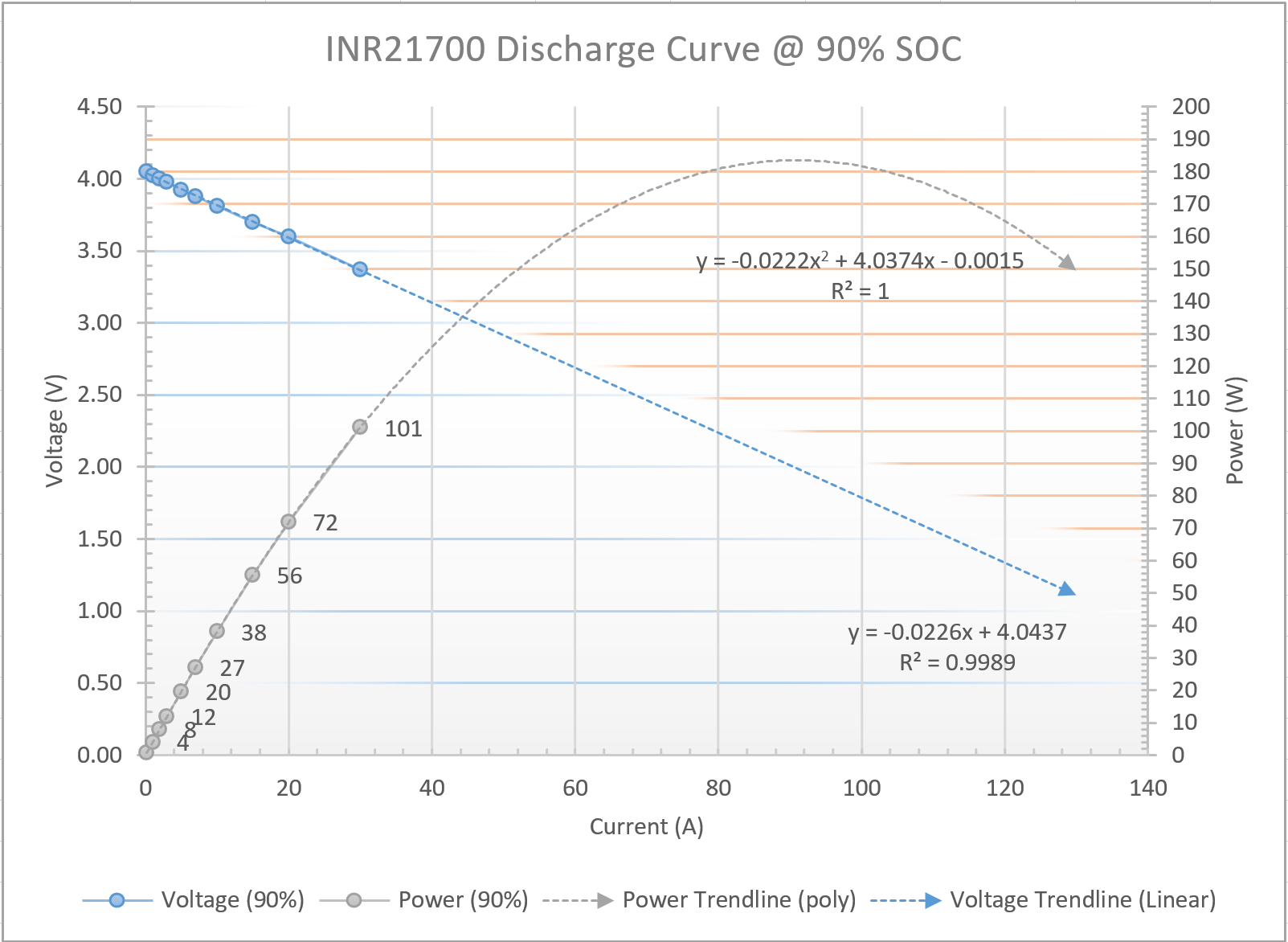

Let's use the data from the earlier INR21700 cell in my last reply and take a snapshot of all the voltages and currents at say 90% SoC and extrapolate where peak power would be if everything was ideal.

The manufacturer specified 25A max discharge, or 5C, which is just around 80W or so. Extrapolating with a perfect fit curve, peak power occurs at 90A or 18C. This is going to damage the cell for sure but we see the expected plateau.

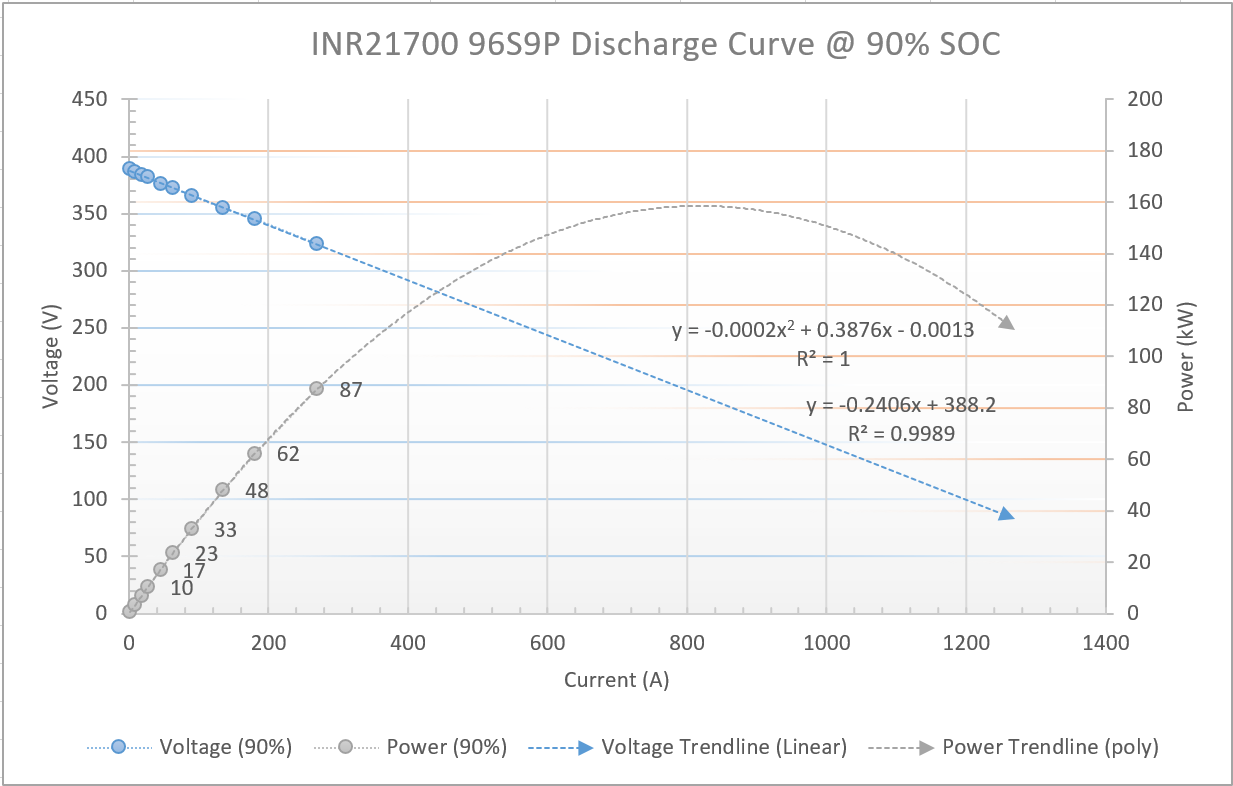

Now let's set the cell up in a 96S9P configuration so we get roughly 45 Ah comparable to a 2015/16 Spark EV and find that idealized plateau again.

at 190V and 800A it falls short of 160kW. The max discharge for these cells would hit around 70-75kW, so we'd probably want a larger configuration of 96S15P to hit the 120kW power figure we want safely. In GM's case, they opted for the hybrid pouch batteries, so they could, reach higher powers for lower capacity and physical size.

Of course, the Spark electronically limits the drive power to 120kW, so is independent of accessory power.

I wouldn't be so sure about this. HVAC is not a part of accessory power, which is fused at 20A in the low voltage fuse block. The HVAC runs on the 300+ VDC battery pack and is fused at 30A along with the coolant heater at 30A. The Auxiliary power control module will feed 1.5kW to the 12-14V automotive systems and is fused on the high voltage battery side at 12A.

On a high level, if you look at the instrument cluster, you see HVAC power as well as battery heater metered to the same total power readout. If drive power is independent from all other power, why is it indicated here? I believe that 120kW is a hard limit set for the common busbar, and power delivered to the traction motor will be throttled first before all other loads. But I'd love to see some data from TorquePro whether it will ever exceed this.

The traction motor is another interesting consideration for why keeping HVAC and other drains off will have an improvement on acceleration. At the heart of every Spark EV is a permanent magnet synchronous motor (PMSM). As RPM rises in a PMSM, back-emf will rise with it, ideally until the back-emf voltages equals the supply voltage and no current flows.

The inverter is responsible for vector control, and creates the 3-phases of rotating magnetic field, as well as current regulation based on the throttle. If voltage is lower due to low SoC, or loads are active that are sagging down the voltage of the batteries, the maximum RPM and torque will be reduced. This is due to the intrinsic back-emf of the motor, as well as the fact that it takes time for current to rise in a motor phase's windings. A higher voltage produces a sharper current angle, resulting in a higher average torque if current can build up fast enough during a firing angle of that particular phase.

Will it do so at some level of low charge? Maybe not. I don't know what kind of "limp home" limits are set in software. It does start to limit things at low charge (it is pretty funny when it offers to turn off the radio). The system will also not allow the battery to go to actual zero. I almost never let it get low, but I will see what happens. and experiment.

I drove up a steep mountain until the battery indicated "LOW". Got as close to zero as I ever got, but then gained 10 kilometers back on the way down. Not sure how much power it was pulling to the traction motor, but car simply got slower and slower. The radio being off probably would've made some difference, but not much. In fact, depending on the song, it could probably feel a little faster :lol: .